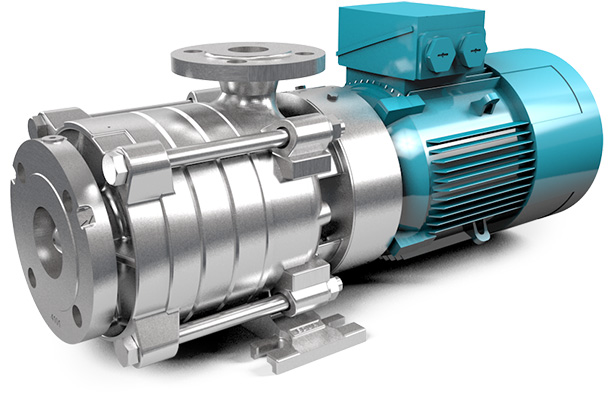

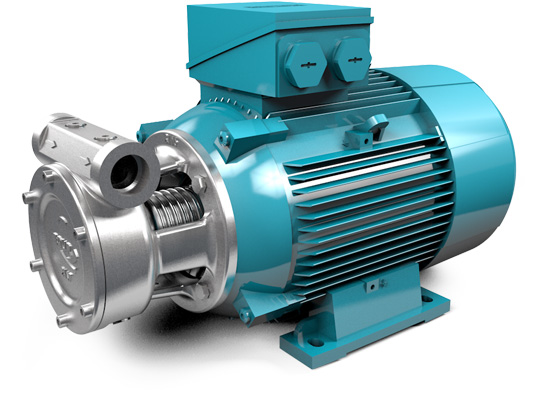

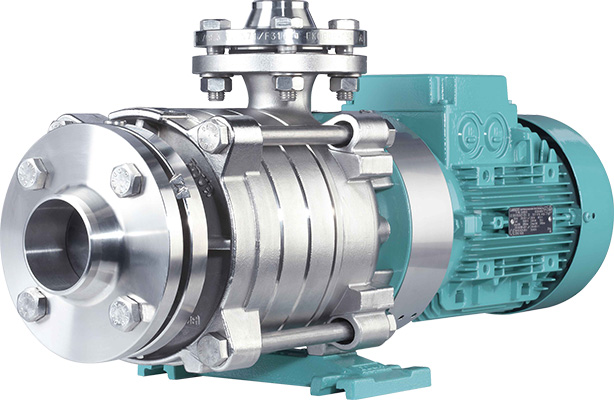

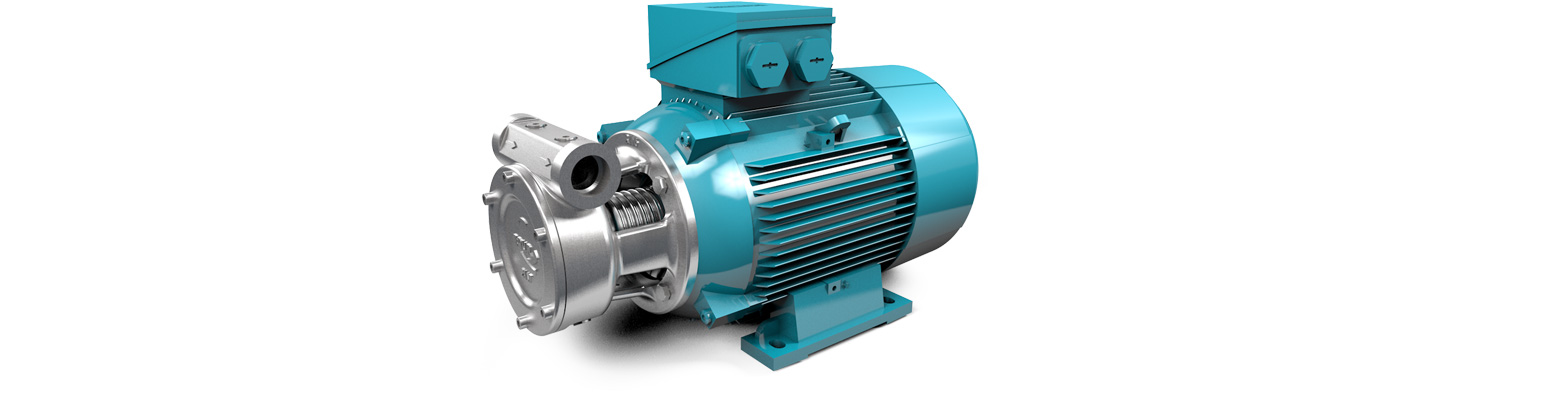

The EDUR PBU Series Peripheral Pump for DAF Bubble Generation for Wastewater Treatment and Ozone Mixing Pump is a truly remarkable centrifugal pump for DAF and Gas-Liquid pumping applications.

The PBU’s ability to reliably pump without cavitation, entrained gases in liquids, with gas contents of up to 15%. Its high energy-efficiency and its technical superiority give it the ability to replace many pumping and control components into a single unit. The PBU Series is truly a leader in the field of DAF Pumps and DAF Pump Systems.

The PBU’s capability to generate stable micro bubbles to supersaturate a system with gas is what sets it apart. The PBU series allows for direct-gas charging into a suction pipe. The necessity for pressure tanks, pumps, control systems and venturi’s are no longer required when using the PBU Pump from EDUR. To mix Ozone into your systems flow, the PBU 210 series could be the best decision for a pump you make this decade with the savings you'll have by removing unnecessary equipment.

The open impeller construction allows for reliable entrapment and direct injection of gases such as Ozone to reach concentration of up to 15%% in solution in your flow system. Other gases can reach the 30% stated above.

The EDUR PBU Series Peripheral Pump for DAF Treatment and Ozone Mixing is also an Ideal solution for traditional DAF (Dissolved Air Flotation) systems with its high gas-content capability to produce “White Water”.

White Water is a term used for when water is supersaturated with micro bubbles of diameters smaller than 30 microns. These bubbles attach themselves to particulate matter and make it buoyant where it can be then floated to the surface for easy collection, eliminating the need for saturation tank air controls and compressed air.

In addition, using EDUR Pumps for producing gas bubbles reduces energy consumption by up to 40% over traditional DAF systems with saturation tanks, air controls and eliminates the need for use of an air compressor!

The PBU Multiphase achieves low velocity of flow with a high degree of dispersion of micro bubbles for optimal enrichment of mixing liquids with gases operating conditions of differential pressures up to 232 PSI and with a flow range of 0-15 GPM at temperatures ranging from -40°F to +284°F with a Viscosity of 115 centistokes.

The EDUR PBU Series Centrifugal Gas Liquid Pump is made in 316 Stainless Steel as standard and is available from stock from EDUR and Shanley Pump and Equipment, Inc. Contact a Shanley Pump salesperson today and inquire about the EDUR PBU Series Centrifugal DAF Treatment or Ozone Mixing Pump.

Close Menu

Close Menu