The EDUR Dissolved Air Flotation (DAF) pump is a very effective way to separate suspended solids and emulsified oils from industrial waste streams. Microscopic air bubbles are produced during normal operation and mixed with waste water containing the suspended contaminates. The small bubbles attach themselves to the suspended particles, which gives them a net positive buoyancy. These buoyant clusters of particles and bubbles rise smoothly to the surface forming a float which is removed by skimming.

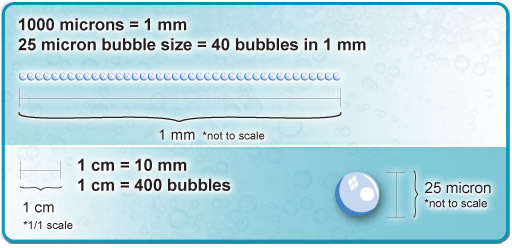

Air and recycled "clean" effluent is introduced to the pump suction. The proportion of air/water is controlled by the operator through simple valves. Under pump discharge pressure this air effluent mixture becomes supersaturated with air micro bubbles. This enriched stream is then recycled back into the dirty effluent and fed to the DAF unit. Up to 35% air can be achieved with 100% saturation and micro bubble size smaller than 30 micron.

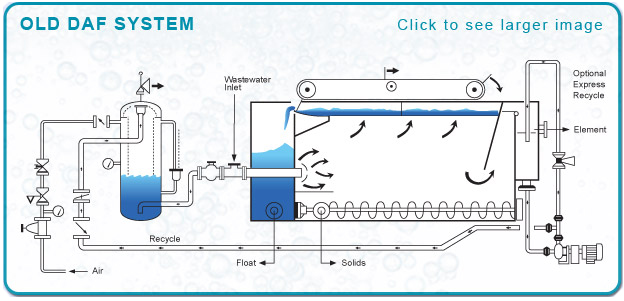

In conventional DAF systems, air saturated water is brought into the flotation tank by by means of compressors, pressure tanks and a tension release valve. Due to the cost and nature of the components, typical DAF systems are a large investment that require more maintenance and service and cost more to operate. An EDUR DAF system is nearly twice as efficient with lower operation costs.

DAF has become successful due to the excellent purification effect, the low consumption of chemicals and the low maintenance and investment costs. With the EDUR system, Dissolved Air Flotation is taken to new levels of efficiency and performance. For more information about the EDUR Dissolved Air Flotation system please feel free to contact a factory trained engineer today at 847-439-9200.

DAF Design Features and Benefits

For DAF applications, EDUR pumps meet the following requirements:

- Long service life because of low wear caused by the inevitable contamination of liquids with solid particles. Please remember, proper selection of materials of construction is critical.

- Steady pumping characteristics even with changing points of operation.

- Sufficient blending of effluent and air to obtain maximum entrainment of air micro bubbles @ 30 micron size.

Standard pumps are not able to meet these requirements. The hydraulic parts of EDUR pumps have been specially designed to cope with problems which arise when pumping effluent/air mixtures. The distinctive feature of the EDUR pump is the impeller, open on both sides, and the innovative hydraulic design of the impeller blades.

EDUR DAF System Construction Materials

The following materials are available for construction of the EDUR DAF Pumps for the following pH levels for the wastewater stream that you will be pumping:

- pH value less than 3 ......................Stainless Steel

- pH value 3 to 5.9 ...........................Bronze

- pH value 6 to 10 ............................Gray Cast Iron

- pH value 11 to 14 ..........................Gray Cast Iron (all iron)

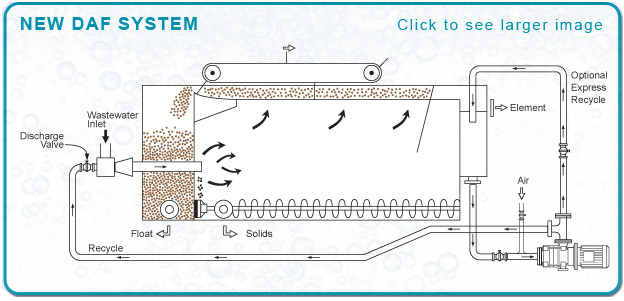

The EDUR DAF System - Efficiency in Action!

A DAF system, with the use of the EDUR DAF Pump providing air enriched recycle effluent. A Typical 100 GPM EDUR Recycle Pump provides 12% air with 93% saturation. Total Power 10 HP. Micro bubble size is smaller than 30 microns.

Previous DAF Systems - Inefficient operability

A Typical DAF System before EDUR. Note the required air tank and controls for providing entrainment. This is eliminated with the use of the EDUR DAF Pump. Typical Unit: 100 GPM recycle, 9% air at 80% entrainment. Total power: 13 HP. And additionally, you need 80 PSI compressed air!

Reduce your costs today by exchanging your old DAF system for a new one from Shanley Pumps and Equipment, Inc. Call us today at 847-439-9200 to talk to one of our engineers, you'll be glad you did.

Close Menu

Close Menu