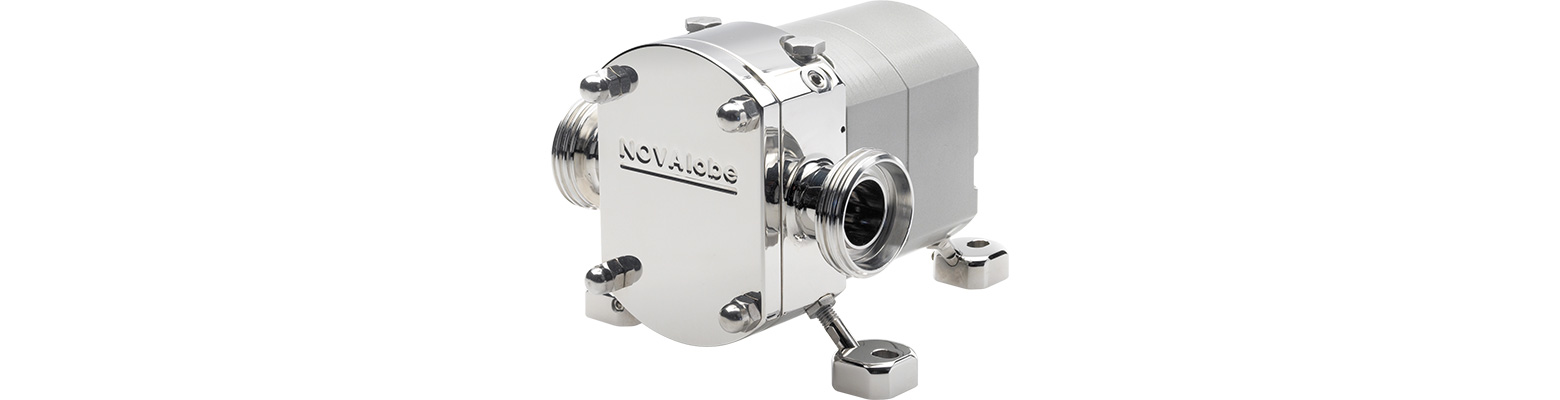

The HILGE NOVAlobe Stainless Steel Hygienic Rotary pump offers reliable and efficient bi-directional pumping operation for high specification pumping tasks requiring the strictest hygienic design criteria from 0.03 to 1.29 liters per revolution at temperatures up to 284°F pressure up to 232-435 PSI.

The NOVAlobe meets the strictest in testing rules and regulations under the following international rules and regulations regarding sterile hygienic pumps:

- EU Machinery Directive

- FDA and GMP regulations

- EU Foodstuff Hygienic Guidelines

- DIN EN 12462 Biotechnology Standard

- Recommendations of the EHEDG (European Hygienic Equipment Design Group)

- Recommendations of the QHD (Qualified Hygienic Design)

The NOVAlobe rotary-pump design makes it appropriate for use in the following industries due to its unique construction:

Food and Beverage Rotary Pumping Applications

- Breweries (e.g. yeast)

- Dairies (e.g. yogurt with fruit)

- Soft-drink applications (e.g. syrup)

- Food processing industries (e.g. chocolate and jam)

- Pharmaceutical Industry

- Rotary Pumping Applications

- Vaccine/fermentation broth

- Blood products

- Biotechnology Cosmetics (e.g. shampoo and lotion)

Other Industrial Rotary Pumping Applications

- Pulp and paper manufacturing pumping

- Textile industry pumping application

- Chemical industry (e.g. oil) pumping applications

- Paints/adhesives pumping applications

Keeping an even temperature while pumping

The HILGE NOVAlobe Rotary Pump has a Thermal Jacket design available for the front cover of the pump which is used to control the temperature of the medium being pumped for both heating and cooling of the product. The design also incorporates a Pressure Relief Valve as a safety feature incorporated into the Aseptic front cover.

Close Menu

Close Menu